- Home

- Urethane Casting Service

Urethane Casting Service

Produce high-fidelity prototypes and low-volume production parts with InstaMFG’s urethane casting services, delivering components in as fast as 7 days. Our process utilizes silicone molds and polyurethane resins to replicate intricate designs with precision, ideal for functional testing and market validation.

Commonly Used Materials:

We offer a variety of polyurethane resins to suit different application needs:

Rigid Polyurethane – for durable, impact-resistant parts

Flexible Polyurethane – for components requiring elasticity

High-Temperature Polyurethane – suitable for parts exposed to elevated temperatures

Transparent Polyurethane – for clear or tinted parts

Flame-Retardant Polyurethane – for applications requiring fire resistance

These materials can be tailored to mimic the properties of production-grade plastics, providing versatility in prototyping and low-volume manufacturing

InstaMFG combines advanced mold design strategies with rapid tooling techniques to deliver production-quality molded parts in just 48 hours. Our high-speed workflow integrates precision-machined inserts, modular base systems, and digital tool path optimization to reduce lead times without compromising part accuracy. Each mold is engineered with high repeatability in mind, achieving tolerances up to ±0.01 mm and supporting a wide range of geometries. We ensure process reliability through closed-loop monitoring of fill behavior, cycle temperature, and part ejection. Additionally, material selection is supported by real-time resin conditioning and pre-processing, ensuring optimal performance for both functional and visual requirements.

Urethane Casting Design Guide

Why Choose Urethane Casting for Rapid Prototyping

Functional Validation & Pre-Production Testing

Customization & Aesthetic Replication

Urethane casting offers extensive customization options to replicate the aesthetics of final products accurately. Through the use of master patterns and silicone molds, intricate surface textures and fine details can be faithfully reproduced. Additionally, a wide range of color options and finishes are available, allowing for the creation of parts that meet specific visual and tactile requirements. This level of customization ensures that prototypes not only function as intended but also provide a realistic representation of the final product's appearance.

Innovative Digital Manufacturing: Revolutionizing Production

Insta MFG revolutionizes manufacturing with instant, high-precision digital solutions, streamlining design to production for modern industries.

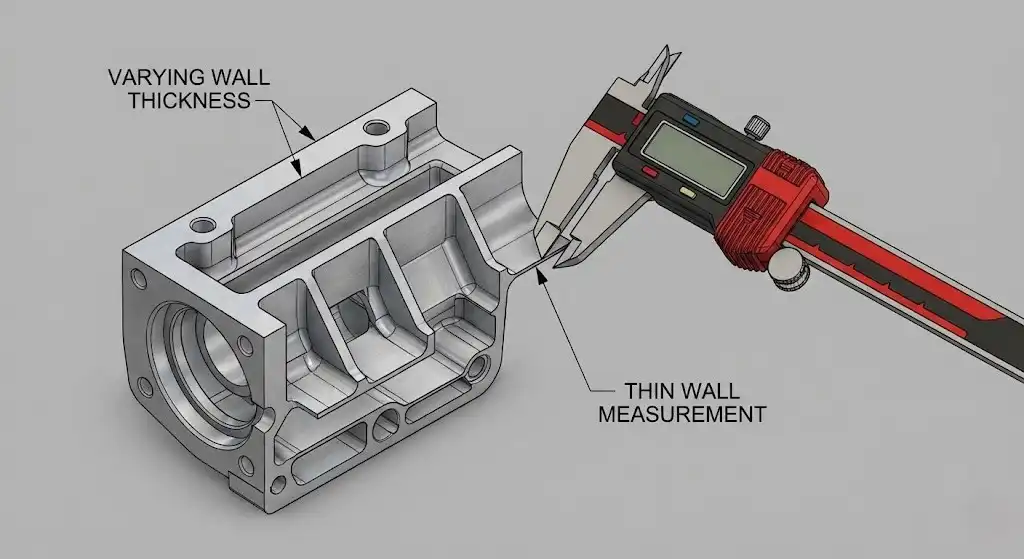

Minimum Wall Thickness: Avoiding Warp & Vibration

Design For Manufacturing Thin walls vibrate. Vibration causes chatter. Chatter ruins parts. Here is the safe limit for CNC machining. Designers love thin walls to save weight. Machinists hate them. When a CNC cutter engages a thin unsupported wall, the material pushes away (deflects) or vibrates. This leads to poor surface finish and dimensional inaccuracy.…

Designing Threaded Holes:Cut Taps vs. Inserts

Design For Assembly Stop stripped threads. Learn the correct depth rules for metal and when to use heat-set inserts for plastics. A simple threaded hole causes 20% of scrap in CNC machining. Why? Because designers often specify threads that are too deep or use the wrong tap type for the material. Rule #1: Drill Depth…

CNC Tolerances Guide:ISO 2768 & Precision Machining

Engineering Standards Why “±0.001mm” on every dimension kills your budget. A practical guide to GD&T and standard tolerances in China. In CNC machining, “Perfect” is the enemy of “Done.” Every decimal point you add to a dimension increases the cost exponentially. Understanding the balance between precision and price is key to effective sourcing. Standard Tolerances…

Injection Molding vs. CNC:The Break-Even Point

Injection Molding vs. CNC:The Break-Even Point Injection Molding vs. CNC:The Break-Even Point Manufacturing Strategy Why “Bridge Production” is the secret weapon for hardware startups to avoid high tooling costs. You have validated your prototype (1-5 units). You aren’t ready for mass production (10,000+). You need 200 units for a pilot run. This is the “Death…

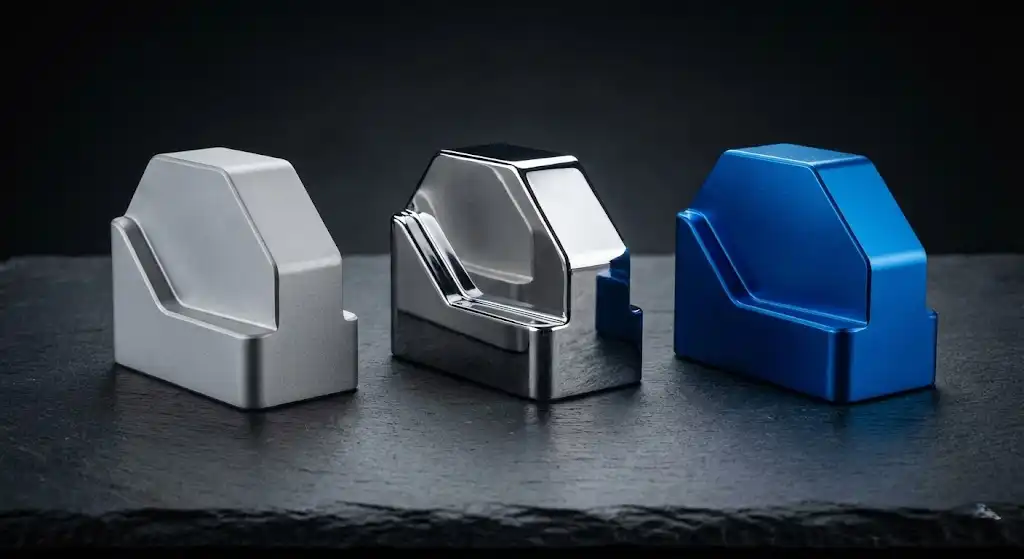

Balancing Aesthetics vs. Cost

Balancing Aesthetics vs. Cost Balancing Aesthetics vs. Cost Design For Manufacturing CNC Surface Finish Guide: Stop over-specifying. Learn when to use Ra 3.2 (As-Machined) vs Ra 0.8 (Polished) to save 20-30% on production costs. The most common cost-driver we see on technical drawings is an unnecessary global surface finish callout (e.g., “All surfaces Ra 0.8”).…

CNC Machining PEEK: Process Control for Critical Applications

Advanced Materials Series A technical analysis of tolerancing, stress relief annealing, and tooling strategies for high-performance thermoplastics. Polyetheretherketone (PEEK) bridges the gap between engineering plastics and metals. For engineers in the Medical Device and aerospace sectors, it is the gold standard. However, a common failure mode is dimensional instability post-machining. Material Grades: Virgin vs. Filled…

CNC Materials

Engineering Resources Stop guessing. A data-driven comparison of Aluminum, Steel, Titanium, and Plastics to help you choose the perfect alloy for your industry. Choosing the right material is often a balancing act between mechanical performance and manufacturing cost. Over-engineer, and your unit price explodes. Under-engineer, and your product fails in the field. At InstaMfg, we…

Strategy: The Smart Way to Source Low-Volume Production in China

2026 Manufacturing S Why “Bridge Production” (50-500 units) is the secret weapon for hardware startups avoiding the “Death Valley” of high MOQ. Here is the classic hardware trap: You have validated your prototype (1-5 units). You aren’t ready for mass production (10,000+ units). You need 200 units for a pilot run or beta test. Most…

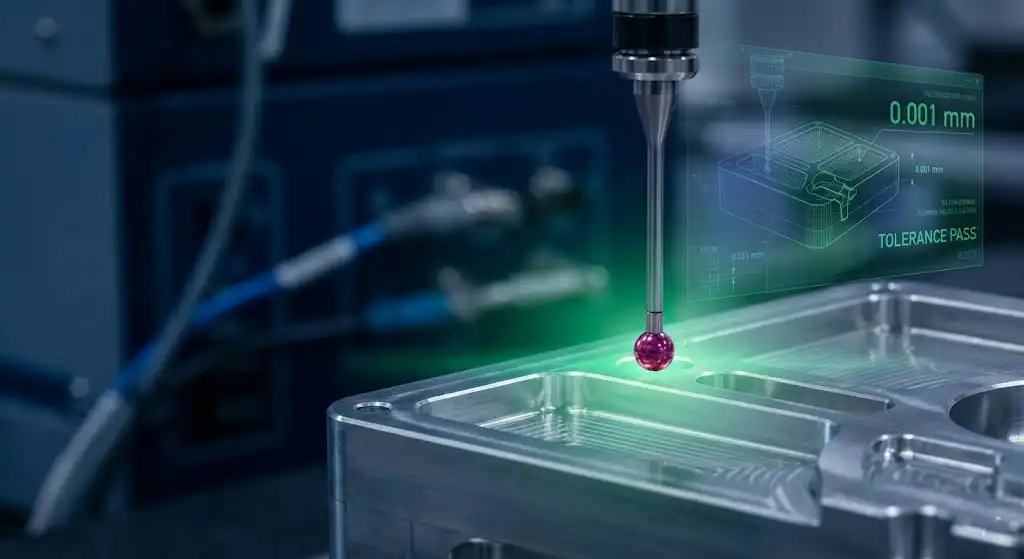

The Truth About Quality Control in Digital Mfg

Quality Assurance (QA) How we use CMM inspections and OES material analysis to exceed ISO 9001 standards and eliminate the risk of offshore manufacturing. “Will the parts fit?” This is the single biggest anxiety for engineers outsourcing production. In the past, “Made in China” sometimes implied inconsistent tolerances. But in the era of Industry 4.0,…

5 Proven Tips to Slash CNC Machining Costs

Design For Manufacturing (DFM) Don’t let over-engineering kill your budget. Learn how Chinese smart factories optimize your CAD files for maximum savings without sacrificing quality. The price of a machined part isn’t random. It’s a direct result of three factors: Material Cost, Machine Run Time, and Setup Time. While you can’t control the market price…

The Evolution of Instant CNC Manufacturing

The Evolution of Instant CNC Manufacturing The Evolution of Instant CNC Manufacturing Manufacturing Insights A technical deep dive into how AI-driven analysis and 5-axis automation are reducing prototype costs by 40% while maintaining ISO-certified quality. The manufacturing landscape has shifted. For decades, engineers accepted a trade-off: you could have parts fast, or you could have…

Digital Manufacturing in 2025: Driving Innovation and Efficiency

In 2025, digital manufacturing integrates AI, IoT, and digital twins to revolutionize production, enhancing efficiency, precision, and adaptability.