Don't let over-engineering kill your budget. Learn how Chinese smart factories optimize your CAD files for maximum savings without sacrificing quality.

The price of a machined part isn't random. It's a direct result of three factors: Material Cost, Machine Run Time, and Setup Time. While you can't control the market price of aluminum, you *can* control how long your part takes to machine.

At InstaMfg, we process thousands of prototypes monthly. The data shows that 70% of cost drivers are locked in during the design phase. Here is how to optimize your designs for our China-based CNC centers.

01. Radius Geometry & Internal Corners

CNC tools are round and rotate. They cannot cut a perfectly sharp internal corner. Requesting a sharp 90° internal corner forces us to use EDM (Electrical Discharge Machining), which can triple the cost.

💡 The Pro Tip:

Add a radius to all internal corners of at least 1/3 the depth of the pocket. This allows us to use larger, stiffer tools that remove material faster, reducing run time.

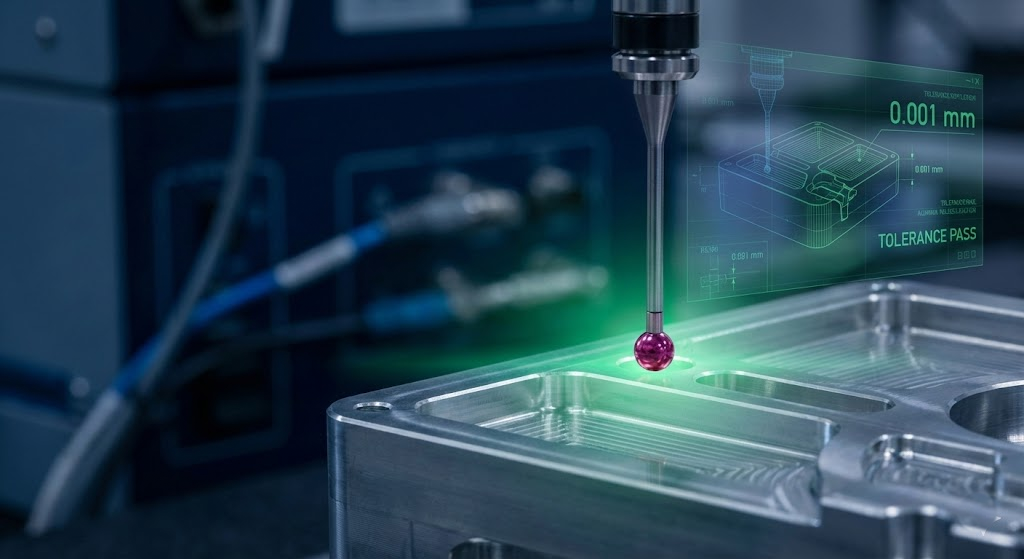

02. Standardize Your Tolerances

Tight tolerances (±0.005mm) require slower feed rates, specialized inspections, and higher scrap rates. Do not apply tight tolerances to every surface.

- Standard: ISO 2768-m (±0.1mm) is free and standard at InstaMfg.

- Precision: Only apply critical tolerances (H7, ±0.01mm) to mating surfaces or bearing bores.

- Loose: For cosmetic surfaces, standard tolerances are sufficient.

03. Understanding the Cost Breakdown

Where does your money go? We analyzed the cost structure of a typical medium-complexity aluminum enclosure produced in our factory.

Machining time (Run Time) is usually the biggest cost driver. Simplifying geometry to reduce runtime has the highest ROI.

Note: "Setup" costs are high for 1 unit but vanish at 100+ units.

04. Material Selection Matters

Just because Titanium is stronger doesn't mean your prototype needs it. Harder materials destroy tools faster and take longer to cut.

| Material | Machinability | Cost Index |

|---|---|---|

| Aluminum 6061 | Excellent | $$ (Baseline) |

| Stainless 304 | Hard | $$$ (+150%) |

| Titanium Gr5 | Difficult | $$$$$ (+400%) |

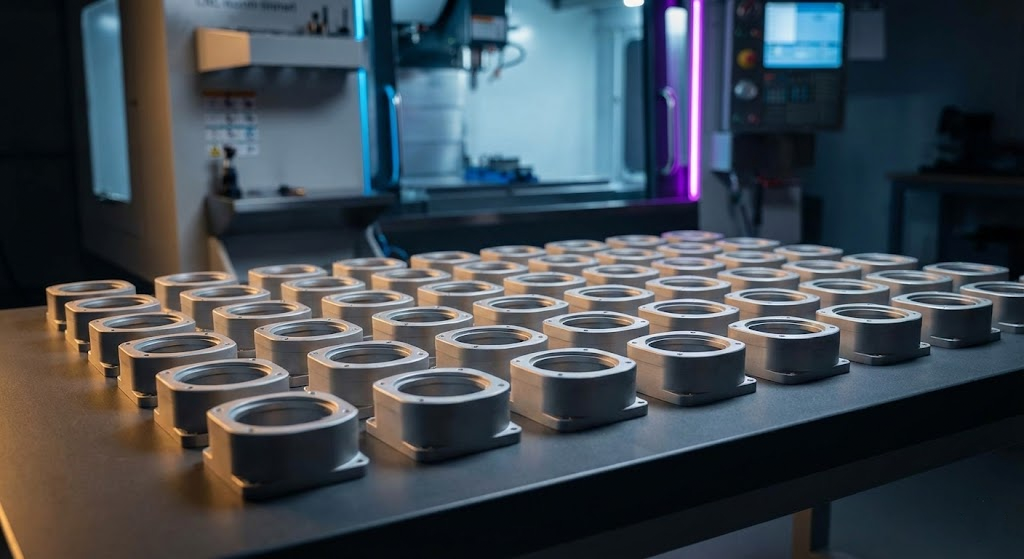

05. Leverage the Volume Curve

CNC machining has high startup costs (CAM programming + Fixturing). If you order 1 part, you pay 100% of that setup. If you order 50 parts, that cost is split 50 ways.

At InstaMfg, our AI quoting engine automatically suggests volume break-points. Often, ordering 10 parts costs only marginally more than ordering 5.

Ready for a competitive quote?

Send us your optimized designs and experience the InstaMfg price advantage.

Get Quote Now