Why "Bridge Production" (50-500 units) is the secret weapon for hardware startups avoiding the "Death Valley" of high MOQ.

Here is the classic hardware trap: You have validated your prototype (1-5 units). You aren't ready for mass production (10,000+ units). You need 200 units for a pilot run or beta test.

Most factories will tell you "No." Their Minimum Order Quantity (MOQ) is too high. Local machine shops will say "Yes," but their price per unit will bankrupt you.

At InstaMfg, we specialize in this exact gap. We call it "Bridge Production." By using high-speed 5-axis automation, we have eliminated the setup costs that traditionally make low-volume orders expensive.

01. Why Low-Volume Manufacturing Wins in 2026

The market moves too fast for traditional tooling. Investing $20,000 in a steel mold for a product that might change in 3 months is risky. Low-volume CNC machining offers agility.

This approach allows you to iterate. You can order 50 units of "Version 1.0", get market feedback, change the CAD, and order 50 units of "Version 1.1" next week. No tooling costs lost.

02. The "Pilot Run" Economics

Many engineers assume that CNC machining is always more expensive than molding. That is true at 10,000 units. But at 500 units? The math changes.

We used our AI quoting engine to compare the Total Cost of Ownership (TCO) for a standard handheld enclosure project.

Fig 1: The "Break-Even Point" where CNC beats Injection Molding.

03. Managing Risks in Remote Manufacturing

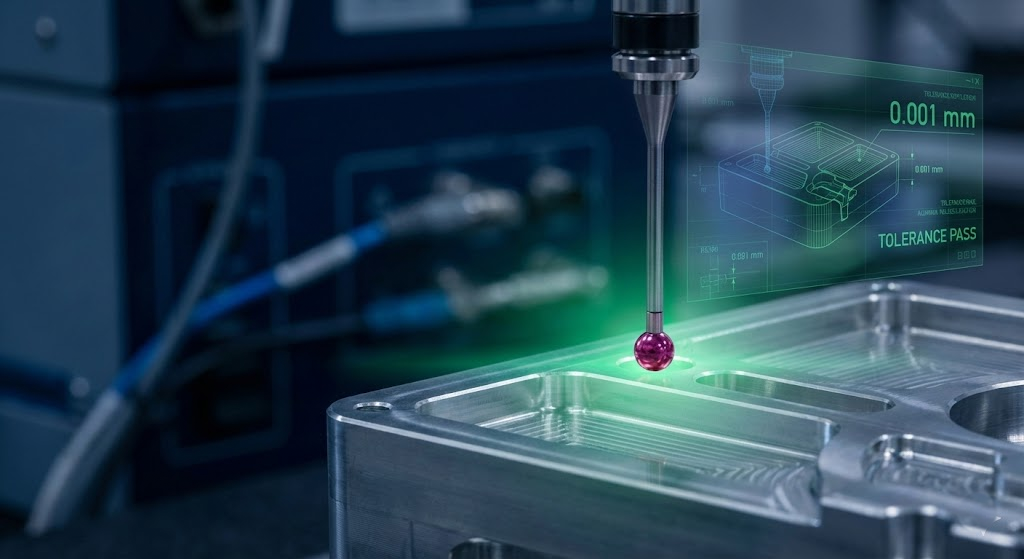

Sourcing from a Chinese CNC factory for critical pilot runs requires trust. We build that trust through what we call "Digital Transparency."

For every low-volume production run, we provide a "First Article Inspection" (FAI) report digitally before the rest of the batch is machined. You approve the data, we run the job.

The Bridge Production Checklist

Ensure your project is ready for low-volume scaling:

- Standardize Threads: Use standard metric taps (M3, M4) to avoid custom tooling delays.

- Surface Finish: Specify "As Machined" for internal parts to save 15% on cost.

- Batching: Ordering 100 units at once is typically 40% cheaper per unit than ordering 10 units ten times.

04. Industries We Serve

Who uses Bridge Production?

- Medical Devices: Pre-clinical trial units (Titanium/PEEK) requiring ISO 13485 compliance standards.

- Robotics & Drones: Custom aluminum brackets for fleet testing.

- Automotive Aftermarket: Limited edition performance parts.

Need 50 parts or 500?

We treat low-volume orders with the same priority as mass production.

Get Instant Quote