Stop guessing. A data-driven comparison of Aluminum, Steel, Titanium, and Plastics to help you choose the perfect alloy for your industry.

Choosing the right material is often a balancing act between mechanical performance and manufacturing cost. Over-engineer, and your unit price explodes. Under-engineer, and your product fails in the field.

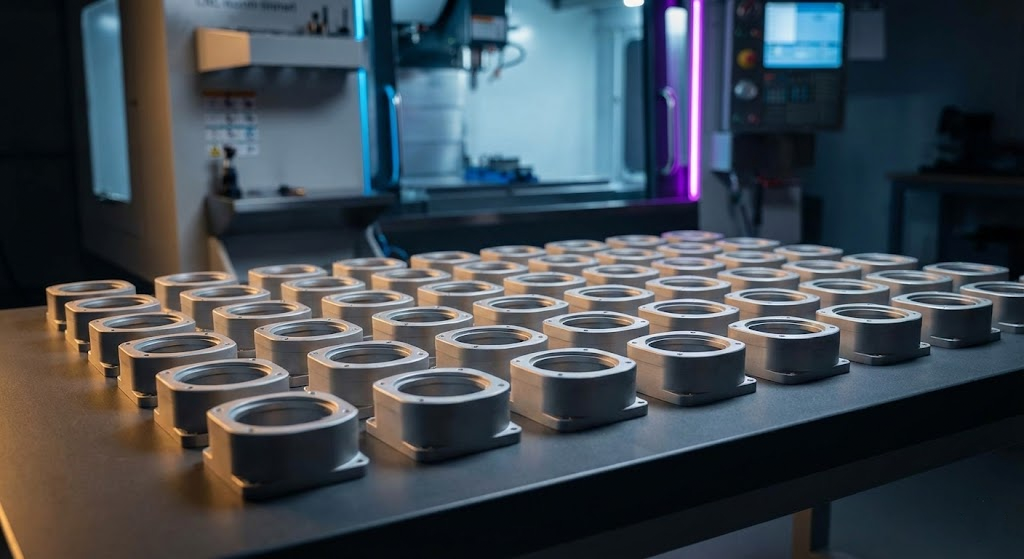

At InstaMfg, we stock over 60 engineering-grade materials in our China facility. This guide breaks down the most popular choices for CNC machining, helping you make an informed decision for your next prototype or production run.

01. The Aluminum Titans: 6061 vs. 7075

Aluminum is the king of CNC machining—lightweight, easy to cut, and corrosion-resistant. But which grade do you need?

| Grade | Key Properties | Best Application |

|---|---|---|

| 6061-T6 | Good weldability, corrosion resistance, low cost. | General purpose enclosures, brackets, consumer electronics. |

| 7075-T6 | High strength (comparable to steel), high fatigue stress. | Aerospace components, high-stress gears, drone frames. |

*Pro Tip: 7075 is roughly 2x the cost of 6061. If you don't need the extreme strength, stick to 6061 to save budget.

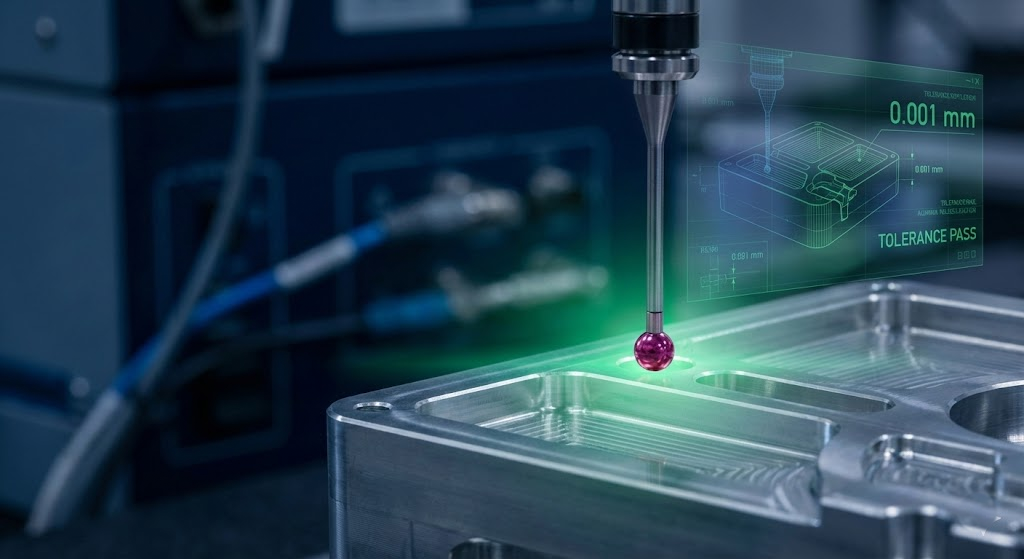

02. Hard Metals: Stainless & Titanium

When aluminum isn't enough, we turn to the hard metals. These require rigid 5-axis machines and specialized tooling, which we provide standard at InstaMfg.

Stainless Steel 304 vs. 316L

Both are excellent, but 316L contains Molybdenum, giving it superior resistance to chlorides (saltwater).

Use 304 for kitchenware or general hardware.

Use 316L for marine environments or medical implants.

Titanium (Ti-6Al-4V)

The highest strength-to-weight ratio of any metal. It is difficult to machine due to heat generation, but essential for aerospace and medical implants.

03. Material Selection Matrix

We plotted the most common materials based on Yield Strength (MPa) vs. Relative Cost. Use this chart to find your "sweet spot."

Fig 1: Higher is Stronger, Right is More Expensive.

04. Engineering Plastics

CNC machining isn't just for metal. We machine thousands of plastic parts for functional testing before injection molding.

- Delrin (POM): The most "machinable" plastic. Low friction, high stiffness. Perfect for gears and sliding mechanisms.

- PEEK: An advanced polymer that withstands high temps (260°C). Used as a metal replacement in medical and aerospace. Expensive but powerful.

- Polycarbonate (PC): Naturally transparent. Used for lenses and light pipes. Requires vapor polishing for optical clarity.

05. Surface Finishes

The material is only half the story. The finish defines the function.

- As-Machined: Visible tool marks. Lowest cost.

- Bead Blast: Matte uniform texture. Hides tool marks.

- Anodizing (Type II & III): Adds color and a hard protective layer (Aluminum only).

- Passivation: Chemical cleaning for Stainless Steel.

From PEEK to Titanium

We have the right material in stock for your rapid prototyping needs.

Start Your Project