Why "±0.001mm" on every dimension kills your budget. A practical guide to GD&T and standard tolerances in China.

In CNC machining, "Perfect" is the enemy of "Done." Every decimal point you add to a dimension increases the cost exponentially. Understanding the balance between precision and price is key to effective sourcing.

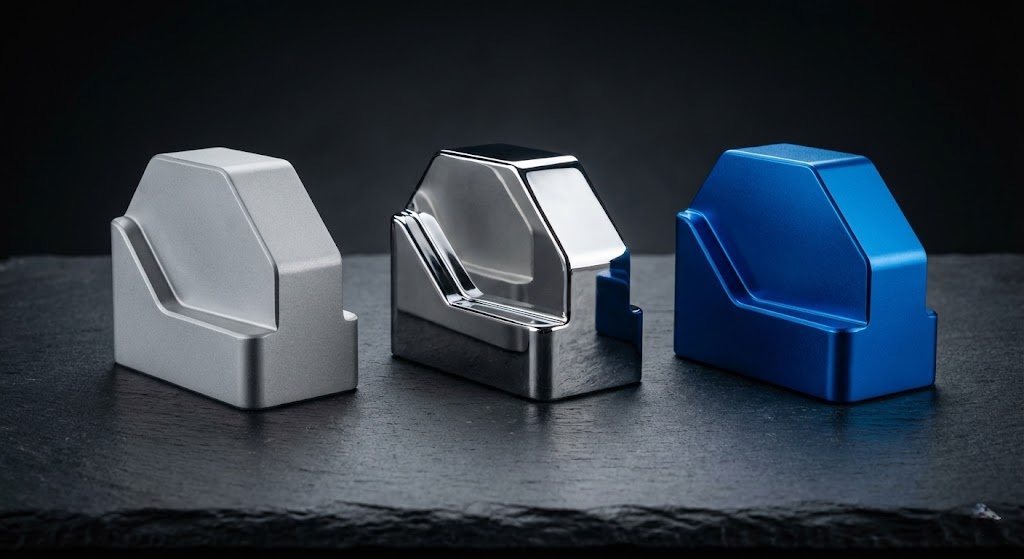

Standard Tolerances (ISO 2768-m)

At InstaMfg, unless otherwise specified, we adhere to ISO 2768-m (Medium). This is the global standard for metal machining. It ensures parts fit together without requiring specialized inspection for every single feature.

| Dimension (mm) | Tolerance (±mm) |

|---|---|

| 0.5 up to 3 | ±0.1 |

| 3 up to 6 | ±0.1 |

| 6 up to 30 | ±0.2 |

| 30 up to 120 | ±0.3 |

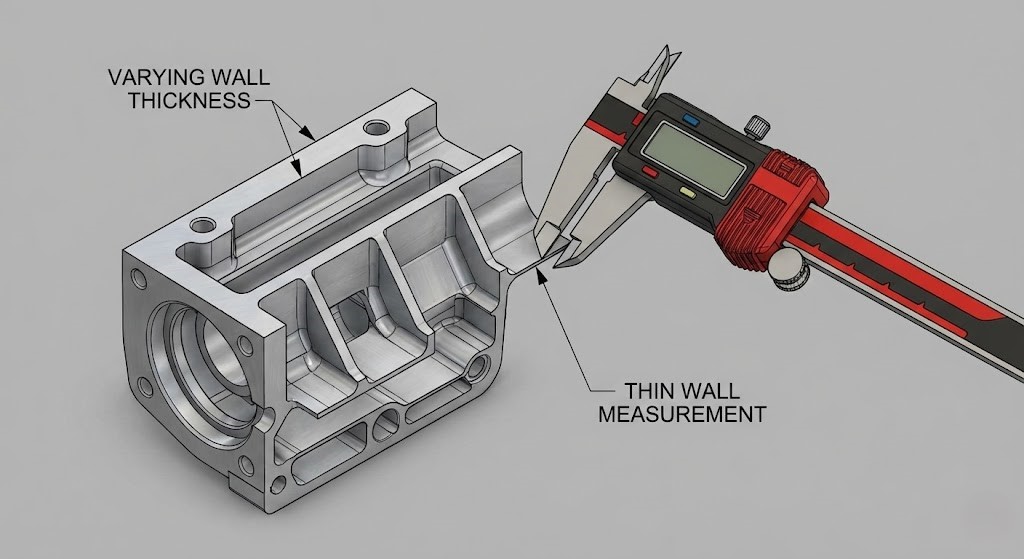

When to use Tight Tolerances?

You should only apply tighter tolerances (e.g., ±0.01mm or H7 fits) to critical features like:

- • Bearing bores and journals.

- • Dowel pin holes for alignment.

- • Mating surfaces for hermetic seals.

See our Materials Guide to see how different alloys hold tolerances differently (e.g., Steel holds better than Nylon).

Fig 1: As tolerance gets tighter (left), cost skyrockets (up).

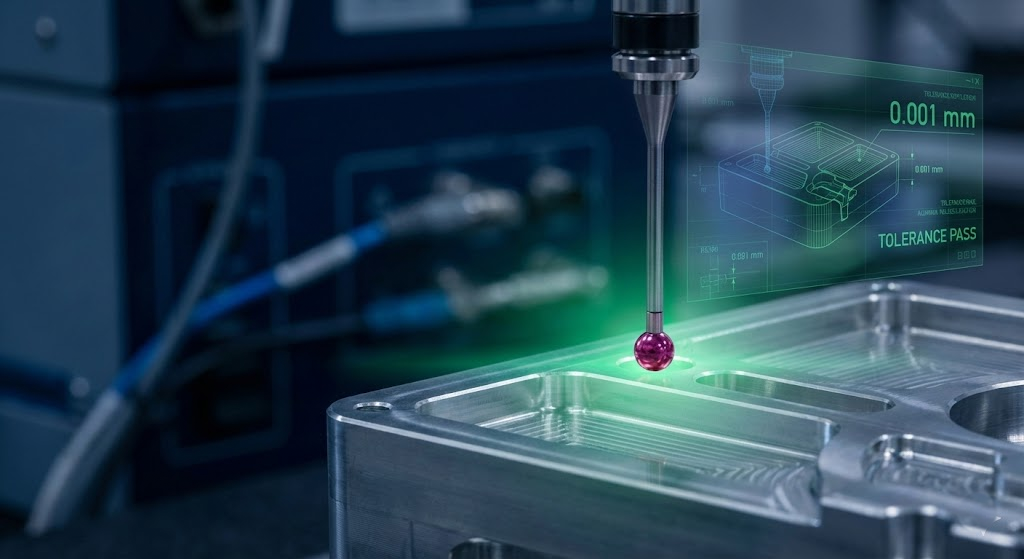

Geometric Dimensioning and Tolerancing (GD&T)

Linear tolerances aren't enough. For complex assemblies, we recommend using GD&T (Flatness, Concentricity, True Position) to communicate design intent.

Need a Tolerance Review?

Upload your drawing. Our DFM engineers will highlight areas where loosening tolerances can save you 30% on cost.

Start DFM Review