Why "Bridge Production" is the secret weapon for hardware startups to avoid high tooling costs.

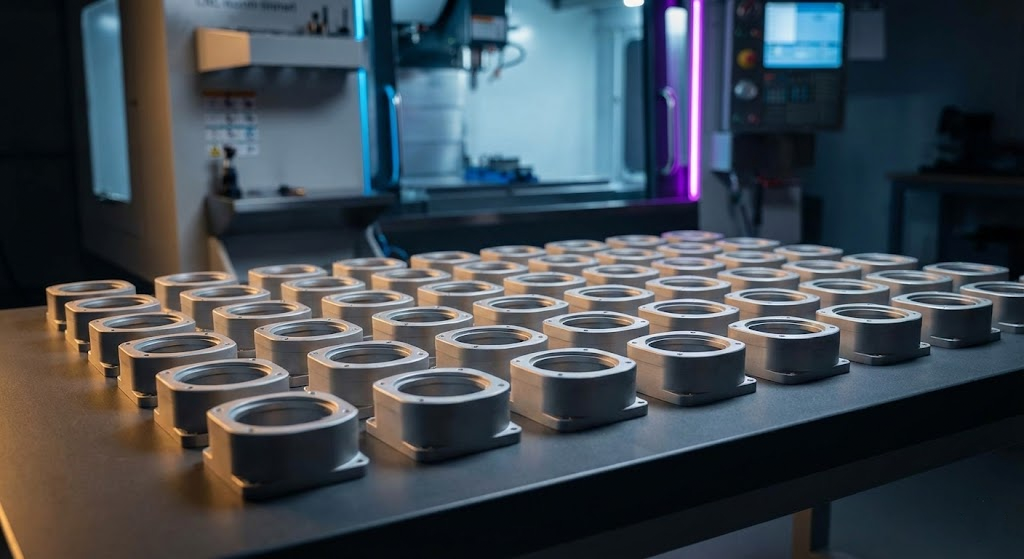

You have validated your prototype (1-5 units). You aren't ready for mass production (10,000+). You need 200 units for a pilot run. This is the "Death Valley" for hardware. Do you pay $10k for a mold? Or pay high prices for local machining?

The Economics of Tooling (NRE)

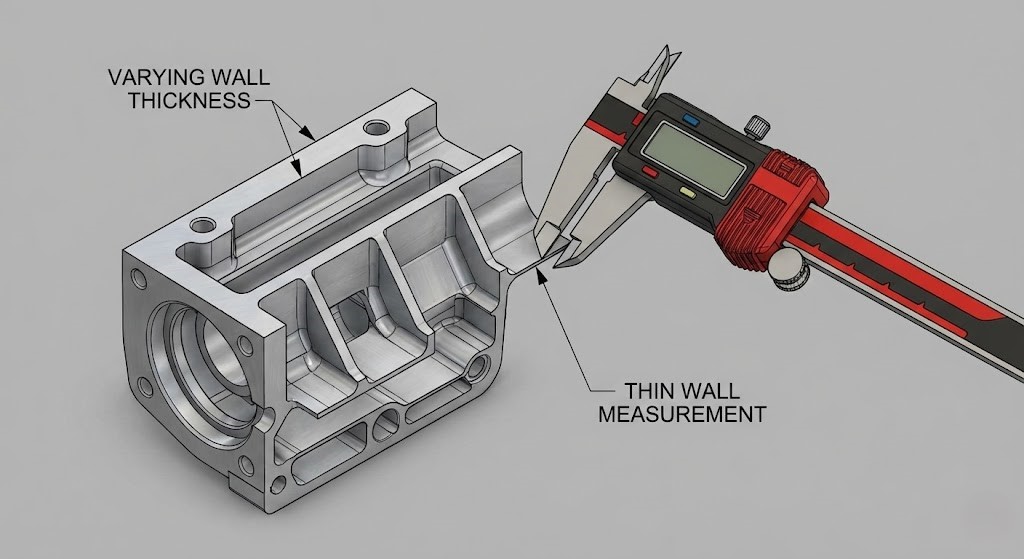

Injection Molding has a high entry barrier (The Mold), but a low unit price. CNC has zero tooling cost, but a higher unit price.

For volumes under 500 units, modern automated CNC is often cheaper and faster. We call this Bridge Production.

Fig 1: CNC (Purple) vs Molding (Gray). CNC wins below ~600 units.

Risks of Early Molding

- Design Lock-in: Once steel is cut, you can't easily change the design. With CNC, you can change the CAD for batch #2 instantly.

- Time to Market: Molds take 4-8 weeks. Bridge CNC production takes 5-7 days.

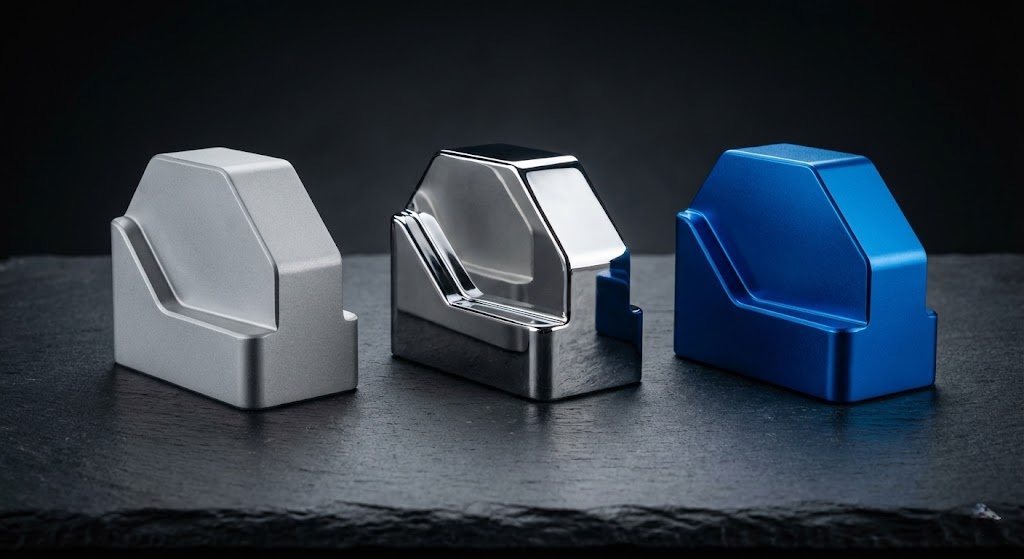

The InstaMfg Advantage

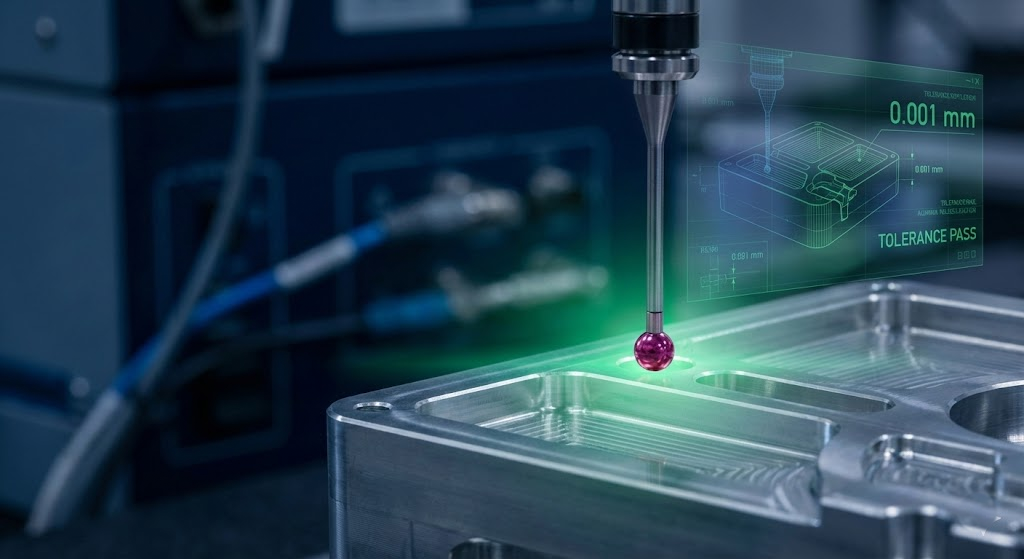

We use the same ISO 9001 Quality Inspection process for pilot runs as we do for mass production. You get production-grade parts without the production-grade commitment.

Running the numbers?

Don't guess. Upload your file to our engine to see the price difference between 50, 100, and 500 units instantly.

Compare Quote Options