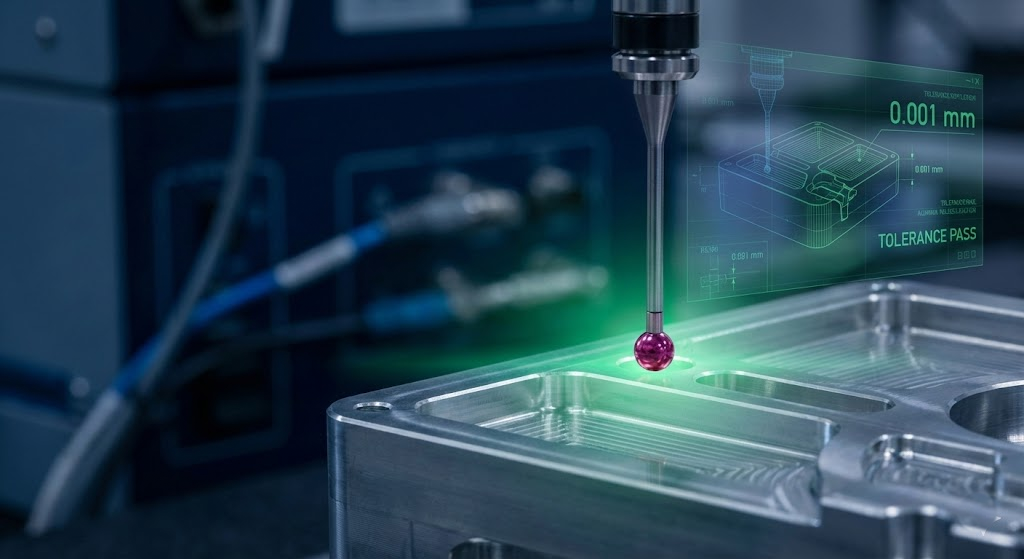

Thin walls vibrate. Vibration causes chatter. Chatter ruins parts. Here is the safe limit for CNC machining.

Designers love thin walls to save weight. Machinists hate them. When a CNC cutter engages a thin unsupported wall, the material pushes away (deflects) or vibrates. This leads to poor surface finish and dimensional inaccuracy.

The Golden Rules for Metals

Minimum Recommended Thickness

For Aluminum & Brass

For Steel & Titanium

Height-to-Thickness Ratio

The thickness is relative to the height. A wall that is 0.5mm thick but only 2mm tall is fine. A wall that is 0.5mm thick and 50mm tall is impossible.

Keep the ratio below 30:1. Anything higher requires special fixturing or slower cutting speeds, which increases production cost.

Plastics Are Different

Plastics warp more easily due to stress release. For materials like ABS or Nylon, aim for a minimum of 1.5mm thickness. Plastics also require consistent wall thickness to prevent warping during machining.

Design Check

Worried your walls are too thin? Our DFM tool checks this automatically.

Upload & Check