- Home

- ABS

ABS CNC Machining – Durable, Lightweight, and Easy to Work With

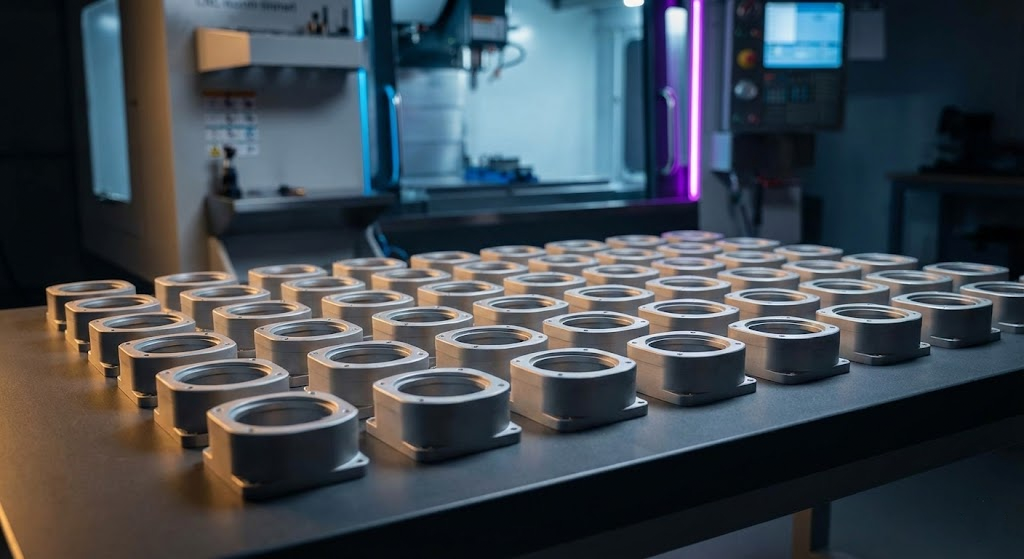

InstaMFG specializes in ABS CNC machining, offering a cost-effective solution for durable, lightweight, and easily workable plastic components. This material is ideal for functional prototypes, protective enclosures, and reliable mechanical parts, providing excellent performance for various applications.

What Is ABS and Why Use It?

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic with excellent machinability and balanced mechanical properties. Its toughness, impact resistance, and ease of finishing make it ideal for general-purpose CNC machined components. Benefits include:

- Strong and rigid with moderate impact resistance

- Lightweight and low cost

- Easy to machine, drill, and bond

- Smooth surface, ideal for painting or plating

Why Choose Us

- 🔧 Easy, Low-Cost Machining

- 🎯 Reliable for Functional Prototypes

- 🖌️ Finish-Ready for Painting and Coating

- 📁 Supports Tight Fits and Multi-Part Assemblies

Where This Material Excels

Consumer Product Housings – Durable and paintable

Prototyping Components – Easy to iterate and finish

Mechanical Parts – Lightweight with good rigidity

For a detailed guide on the properties and composition of this versatile material, learn more about Acrylonitrile Butadiene Styrene (ABS) plastic here.

ABS CNC Machining Made Simple & Effective

ABS is forgiving to work with and offers excellent dimensional stability. Our optimized CNC processes deliver clean edges and accurate fits, with options for post-machining cosmetic finishes and tight-tolerance mating parts.

Innovative Digital Manufacturing: Revolutionizing Production

Insta MFG revolutionizes manufacturing with instant, high-precision digital solutions, streamlining design to production for modern industries.

The Ultimate Guide to

CNC Materials

CNC Materials

Engineering Resources Stop guessing. A data-driven comparison of Aluminum, Steel, Titanium, and Plastics to help you choose the perfect alloy for your industry. Choosing the right material is often a balancing act between mechanical performance and manufacturing cost. Over-engineer, and your unit price explodes. Under-engineer, and your product fails in the field. At InstaMfg, we…

trategy The Smart Way to Source

Low-Volume Production in China

Low-Volume Production in China

2026 Manufacturing S Why “Bridge Production” (50-500 units) is the secret weapon for hardware startups avoiding the “Death Valley” of high MOQ. Here is the classic hardware trap: You have validated your prototype (1-5 units). You aren’t ready for mass production (10,000+ units). You need 200 units for a pilot run or beta test. Most…

The Truth About

Quality Control in Digital Mfg

Quality Control in Digital Mfg

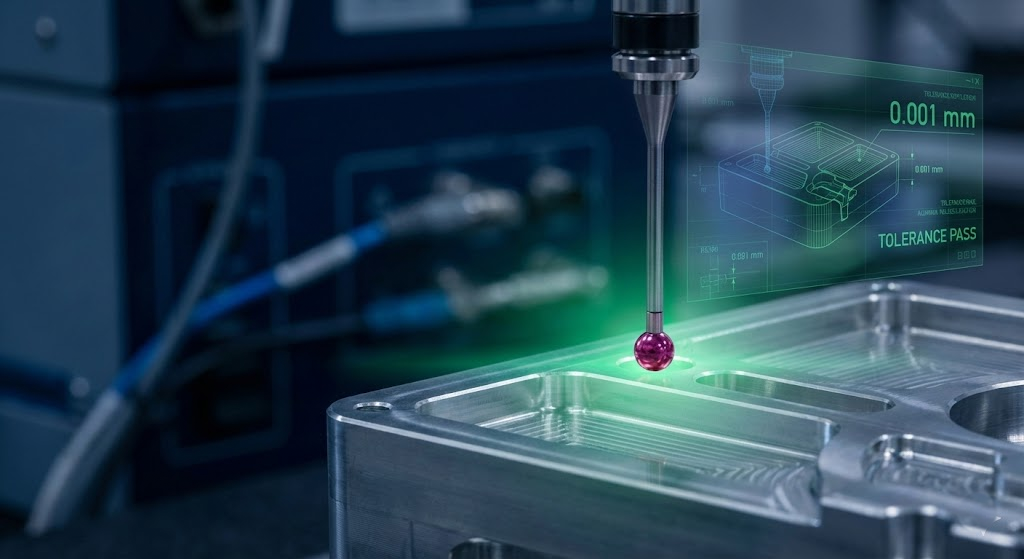

Quality Assurance (QA) How we use CMM inspections and OES material analysis to exceed ISO 9001 standards and eliminate the risk of offshore manufacturing. “Will the parts fit?” This is the single biggest anxiety for engineers outsourcing production. In the past, “Made in China” sometimes implied inconsistent tolerances. But in the era of Industry 4.0,…

5 Proven Tips to Slash

CNC Machining Costs

CNC Machining Costs

Design For Manufacturing (DFM) Don’t let over-engineering kill your budget. Learn how Chinese smart factories optimize your CAD files for maximum savings without sacrificing quality. The price of a machined part isn’t random. It’s a direct result of three factors: Material Cost, Machine Run Time, and Setup Time. While you can’t control the market price…

The Evolution of Instant CNC Manufacturing

The Evolution of Instant CNC Manufacturing The Evolution of Instant CNC Manufacturing Manufacturing Insights A technical deep dive into how AI-driven analysis and 5-axis automation are reducing prototype costs by 40% while maintaining ISO-certified quality. The manufacturing landscape has shifted. For decades, engineers accepted a trade-off: you could have parts fast, or you could have…

Digital Manufacturing in 2025: Driving Innovation and Efficiency

In 2025, digital manufacturing integrates AI, IoT, and digital twins to revolutionize production, enhancing efficiency, precision, and adaptability.