A technical deep dive into how AI-driven analysis and 5-axis automation are reducing prototype costs by 40% while maintaining ISO-certified quality.

The manufacturing landscape has shifted. For decades, engineers accepted a trade-off: you could have parts fast, or you could have them cheap. Getting both meant sacrificing quality. Today, that trade-off is obsolete.

At InstaMfg, we have engineered a solution that bypasses traditional bottlenecks. By integrating computational geometry analysis directly with our factory floor in China, we eliminate the manual "Request for Quote" (RFQ) lag time. But speed is worthless without precision. Here is how we bridge that gap.

01. The 5-Axis Advantage

Most budget-friendly machine shops rely on 3-axis milling centers. While effective for simple prismatic parts, they require manual repositioning for complex geometries. This "fixturing" process is where 60% of manufacturing errors occur and where labor costs skyrocket.

We utilize 5-Axis Simultaneous Machining. This technology allows the cutting tool to maintain a constant tangent to the machining surface.

Single Setup Accuracy

By machining 5 sides of a part in one hold, we maintain global tolerances of ±0.01mm, eliminating stack-up errors found in multi-setup processes.

Complex Geometries

Undercuts, steep walls, and organic shapes (like impellers) are machined without special custom fixtures, significantly lowering NRE costs.

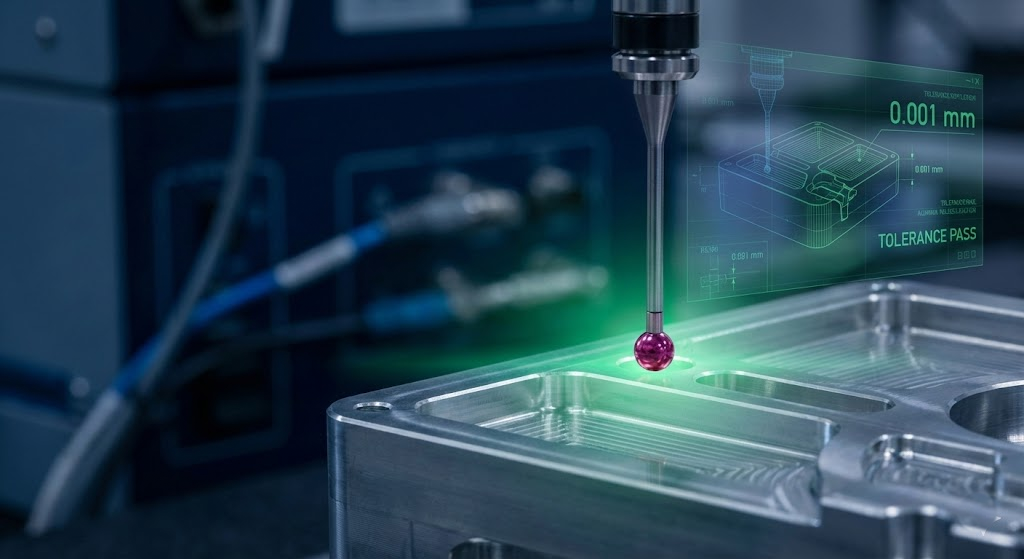

02. Quality Assurance & ISO Standards

Manufacturing in China often raises questions about quality control. We address this with transparency and data. Every part leaving our facility undergoes a rigorous inspection process governed by our ISO 9001:2015 certified quality management system.

The Inspection Workflow:

- Material Verification: Every batch of raw metal arrives with an OES (Optical Emission Spectrometry) analysis to verify chemical composition.

- In-Process Probing: Renishaw probes verify critical dimensions while the part is still on the machine.

- Final CMM Report: Before shipping, a Coordinate Measuring Machine (CMM) verifies tolerances, generating a report included with your shipment.

This is not just "checking parts"; it is a digital chain of custody that ensures the Aluminum 6061 you specified is exactly what you receive.

03. Data-Driven Speed

We analyzed production data from over 500 recent projects. The graph below illustrates the time savings achieved through our digital thread compared to traditional offline machine shops.

Fig 1: Production Lifecycle Comparison (Design to Shipping).

04. Material Inventory Strategy

Speed implies availability. We do not order material *after* you place an order. We maintain a strategic inventory of the most common engineering-grade materials to ensure machining starts immediately.

| Material | Properties | Availability |

|---|---|---|

| Aluminum 6061-T6 | Excellent machinability, high strength-to-weight. | In Stock |

| Stainless 304 | Corrosion resistant, medical grade. | In Stock |

| Delrin (POM) | Low friction, high stiffness plastic. | In Stock |

| Brass C360 | High conductivity, aesthetic finish. | In Stock |

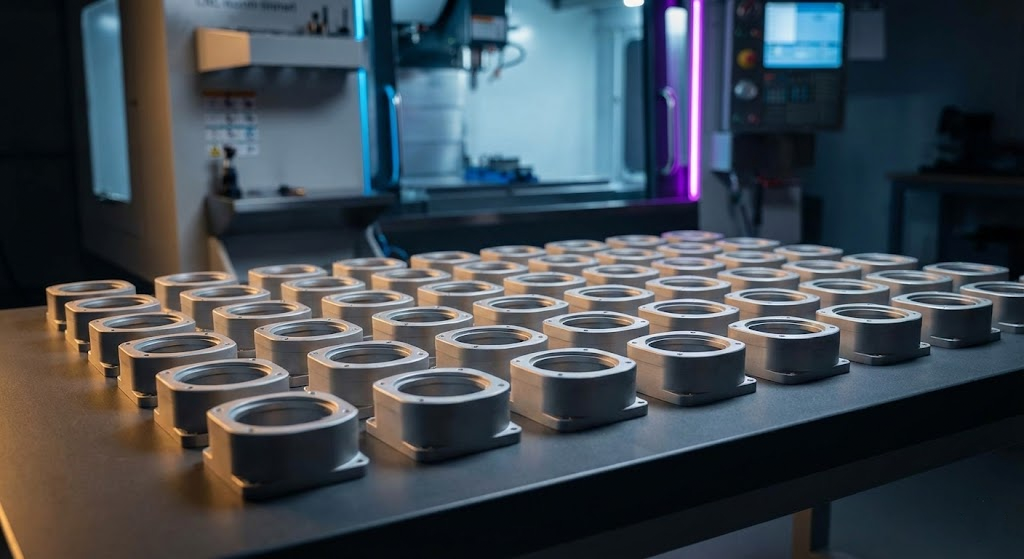

Whether you are developing consumer electronics, automotive components, or medical devices, our facility is equipped to handle low-volume production (1-1000 units) with the same care as mass production.

Ready to optimize your supply chain?

Join thousands of engineers who trust InstaMfg for reliable, low-cost CNC manufacturing in China.

Get in Touch