- Home

- Surface Finishing

Surface Finishing Services

Surface finishing encompasses mechanical, chemical, and thermal processes that modify a part’s exterior to improve functional and visual qualities. By removing micro-burrs, adding protective coatings, or texturing surfaces, we ensure your components meet exacting specifications for durability and finish

Key Benefits:

Enhanced Durability, Corrosion Resistance & Aesthetic Appeal with the following advantages:

- Enhanced Corrosion & Wear Resistance: Advanced treatments reduce material degradation, extending part life .

- Improved Aesthetics: Customizable finishes—from matte to mirror polish—elevate brand perception.

- Tight Tolerances Maintained: In-house controls ensure uniform coating thickness without warping .

- Reduced Waste & Faster Turnaround: Streamlined workflows lower scrap rates and speed delivery

Applications:

Ideal for aerospace brackets, medical implants, automotive parts, and consumer electronics housings—anywhere surface integrity is mission-critical

“Thanks to InstaMFG’s precision electropolishing, our fuel injector housings now exceed OEM specs and pass every endurance test.”

— Lead Engineer, AeroTech Dynamics

Get a free finish analysis → Request a Quote

Process Workflow

1. Preparation & Cleaning

2. Treatment Application

3. Quality Inspection

4. Final Polishing & Packaging

1. Preparation & Cleaning

Degreasing and blast-cleaning remove contaminants.

2. Treatment Application

Electropolishing, anodizing, plating, or powder coating.

3. Quality Inspection

Thickness gauges and adhesion tests verify finish.

4. Final Polishing & Packaging

Ensures pristine appearance and protection.

Why InstaMFG?

- End-to-End Service: From DFM reviews to post-machining assembly Quality Assurance: ISO 9001 traceable inspections on every lot Rapid Turnaround: Express prototyping and scalable production Dedicated Support: Your single point of contact from RFQ to delivery

- Quality Assurance: ISO 9001 traceable inspections on every lot

- Rapid Turnaround: Express prototyping and scalable production

- Dedicated Support: Your single point of contact from RFQ to delivery

Innovative Digital Manufacturing: Revolutionizing Production

Insta MFG revolutionizes manufacturing with instant, high-precision digital solutions, streamlining design to production for modern industries.

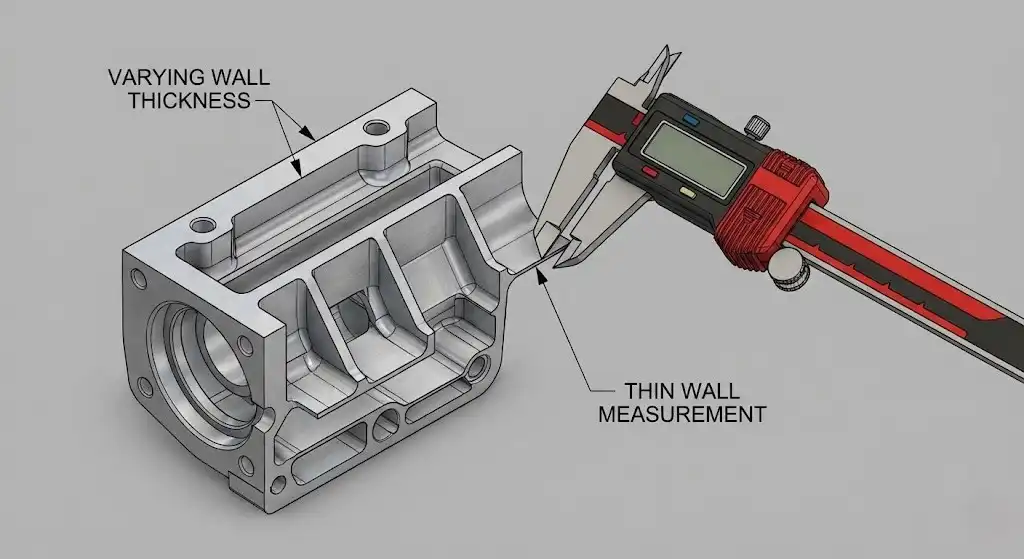

Minimum Wall Thickness: Avoiding Warp & Vibration

Design For Manufacturing Thin walls vibrate. Vibration causes chatter. Chatter ruins parts. Here is the safe limit for CNC machining. Designers love thin walls to save weight. Machinists hate them. When a CNC cutter engages a thin unsupported wall, the material pushes away (deflects) or vibrates. This leads to poor surface finish and dimensional inaccuracy.…

Designing Threaded Holes:Cut Taps vs. Inserts

Design For Assembly Stop stripped threads. Learn the correct depth rules for metal and when to use heat-set inserts for plastics. A simple threaded hole causes 20% of scrap in CNC machining. Why? Because designers often specify threads that are too deep or use the wrong tap type for the material. Rule #1: Drill Depth…

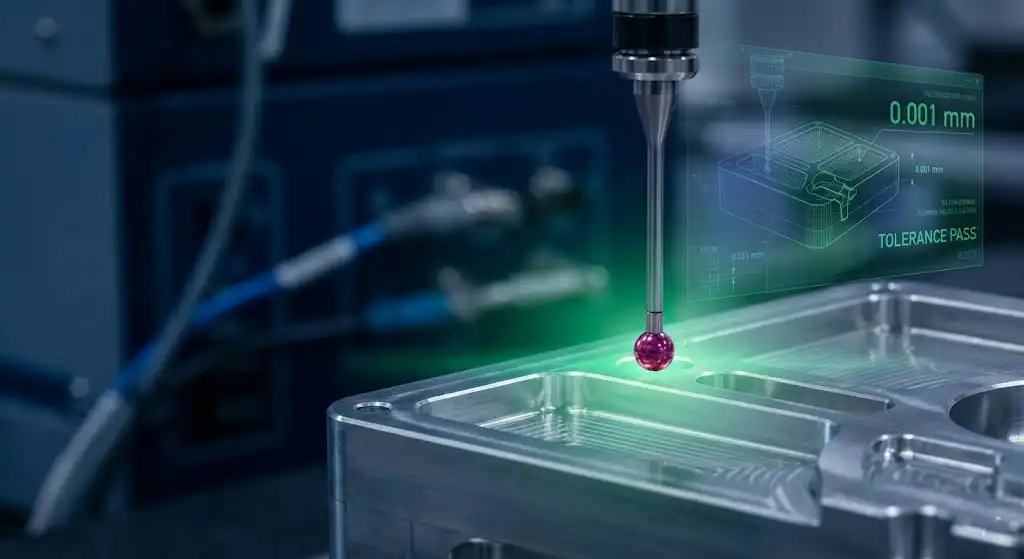

CNC Tolerances Guide:ISO 2768 & Precision Machining

Engineering Standards Why “±0.001mm” on every dimension kills your budget. A practical guide to GD&T and standard tolerances in China. In CNC machining, “Perfect” is the enemy of “Done.” Every decimal point you add to a dimension increases the cost exponentially. Understanding the balance between precision and price is key to effective sourcing. Standard Tolerances…

Injection Molding vs. CNC:The Break-Even Point

Injection Molding vs. CNC:The Break-Even Point Injection Molding vs. CNC:The Break-Even Point Manufacturing Strategy Why “Bridge Production” is the secret weapon for hardware startups to avoid high tooling costs. You have validated your prototype (1-5 units). You aren’t ready for mass production (10,000+). You need 200 units for a pilot run. This is the “Death…

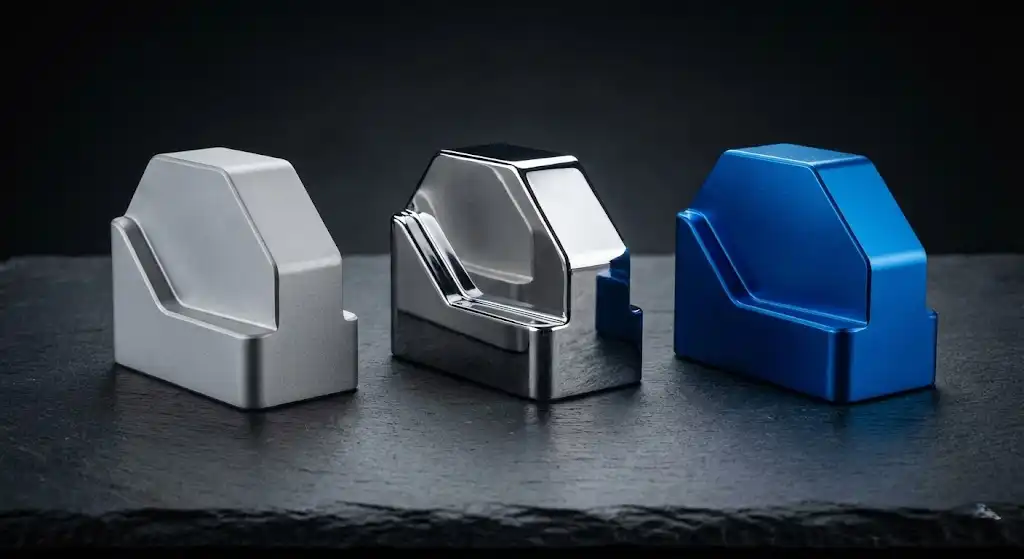

Balancing Aesthetics vs. Cost

Balancing Aesthetics vs. Cost Balancing Aesthetics vs. Cost Design For Manufacturing CNC Surface Finish Guide: Stop over-specifying. Learn when to use Ra 3.2 (As-Machined) vs Ra 0.8 (Polished) to save 20-30% on production costs. The most common cost-driver we see on technical drawings is an unnecessary global surface finish callout (e.g., “All surfaces Ra 0.8”).…

CNC Machining PEEK: Process Control for Critical Applications

Advanced Materials Series A technical analysis of tolerancing, stress relief annealing, and tooling strategies for high-performance thermoplastics. Polyetheretherketone (PEEK) bridges the gap between engineering plastics and metals. For engineers in the Medical Device and aerospace sectors, it is the gold standard. However, a common failure mode is dimensional instability post-machining. Material Grades: Virgin vs. Filled…

CNC Materials

Engineering Resources Stop guessing. A data-driven comparison of Aluminum, Steel, Titanium, and Plastics to help you choose the perfect alloy for your industry. Choosing the right material is often a balancing act between mechanical performance and manufacturing cost. Over-engineer, and your unit price explodes. Under-engineer, and your product fails in the field. At InstaMfg, we…

Strategy: The Smart Way to Source Low-Volume Production in China

2026 Manufacturing S Why “Bridge Production” (50-500 units) is the secret weapon for hardware startups avoiding the “Death Valley” of high MOQ. Here is the classic hardware trap: You have validated your prototype (1-5 units). You aren’t ready for mass production (10,000+ units). You need 200 units for a pilot run or beta test. Most…

The Truth About Quality Control in Digital Mfg

Quality Assurance (QA) How we use CMM inspections and OES material analysis to exceed ISO 9001 standards and eliminate the risk of offshore manufacturing. “Will the parts fit?” This is the single biggest anxiety for engineers outsourcing production. In the past, “Made in China” sometimes implied inconsistent tolerances. But in the era of Industry 4.0,…

5 Proven Tips to Slash CNC Machining Costs

Design For Manufacturing (DFM) Don’t let over-engineering kill your budget. Learn how Chinese smart factories optimize your CAD files for maximum savings without sacrificing quality. The price of a machined part isn’t random. It’s a direct result of three factors: Material Cost, Machine Run Time, and Setup Time. While you can’t control the market price…

The Evolution of Instant CNC Manufacturing

The Evolution of Instant CNC Manufacturing The Evolution of Instant CNC Manufacturing Manufacturing Insights A technical deep dive into how AI-driven analysis and 5-axis automation are reducing prototype costs by 40% while maintaining ISO-certified quality. The manufacturing landscape has shifted. For decades, engineers accepted a trade-off: you could have parts fast, or you could have…

Digital Manufacturing in 2025: Driving Innovation and Efficiency

In 2025, digital manufacturing integrates AI, IoT, and digital twins to revolutionize production, enhancing efficiency, precision, and adaptability.