A technical analysis of tolerancing, stress relief annealing, and tooling strategies for high-performance thermoplastics.

Polyetheretherketone (PEEK) bridges the gap between engineering plastics and metals. For engineers in the Medical Device and aerospace sectors, it is the gold standard. However, a common failure mode is dimensional instability post-machining.

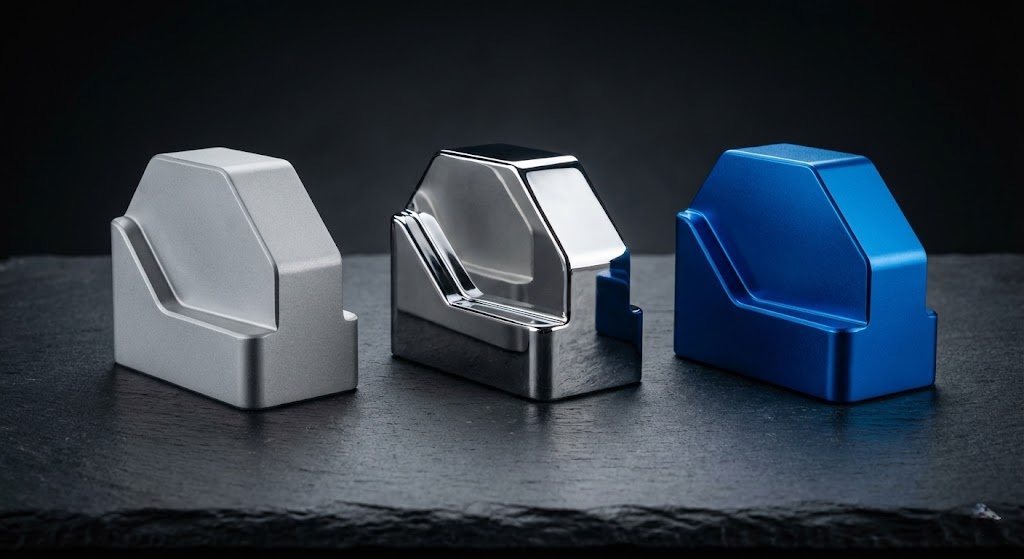

Material Grades: Virgin vs. Filled

Understanding the grade is the first step in DFM.

1. Virgin PEEK (Unfilled)

Standard grade. Compliant with FDA regulations. Best for electrical insulators and fluid manifolds.

2. Carbon-Filled PEEK (30% CF)

Reinforced with carbon fibers for higher stiffness and reduced thermal expansion.

The Critical Process: Annealing

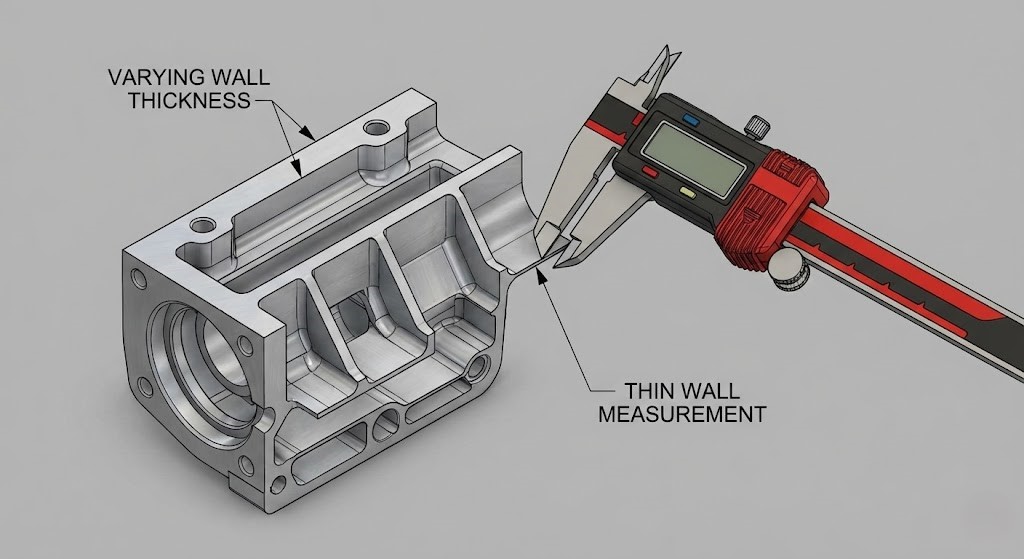

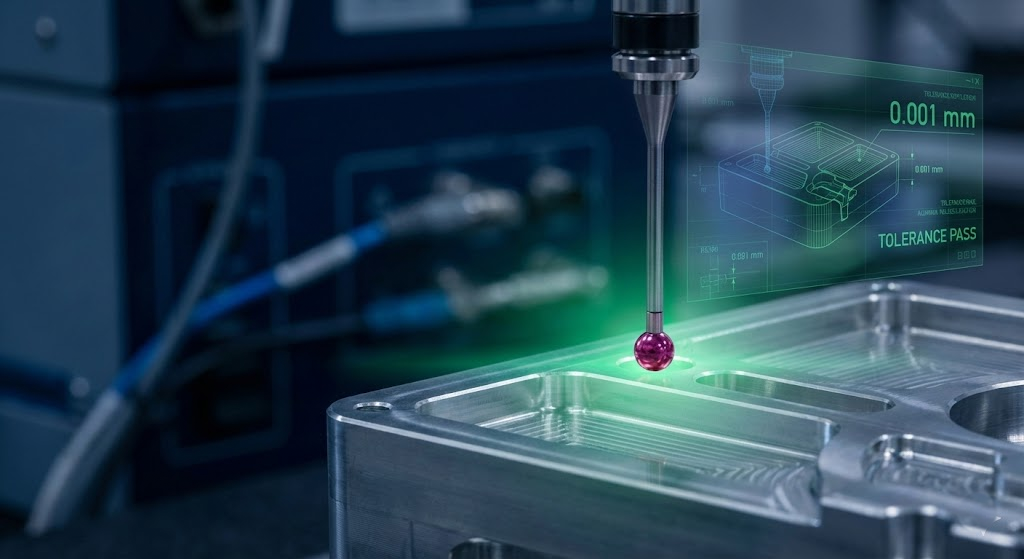

To hold tight tolerances (±0.05mm), PEEK must undergo an annealing cycle before the finishing pass to release internal extrusion stresses.

Fig 1: InstaMfg Stress-Relief Cycle.

We rough-machine to within 0.5mm, anneal, and then use our 5-Axis Machining Centers for the final pass. This ensures stability.

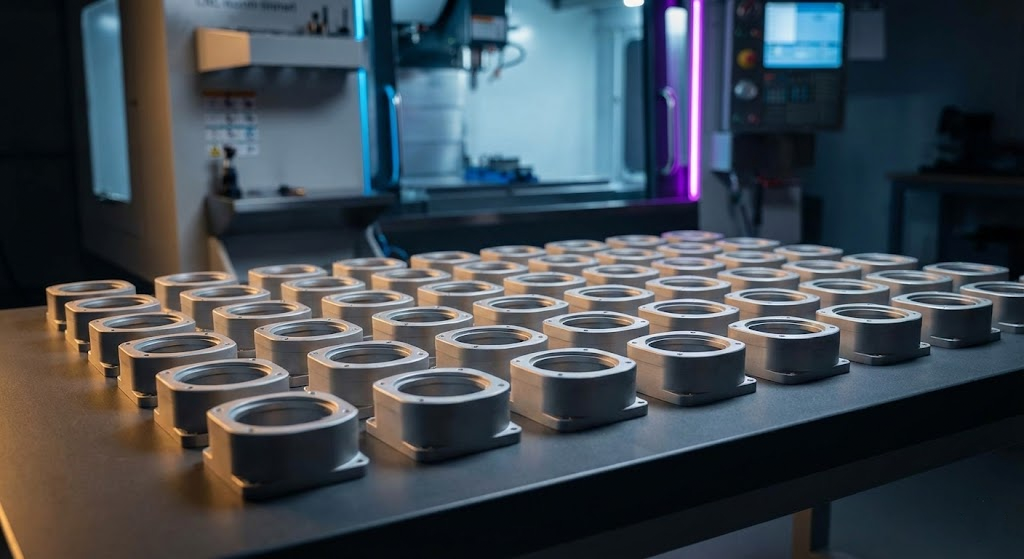

Cost Drivers & Optimization

- Stock Sizes: Design parts to fit standard rod diameters (20mm, 30mm) to minimize waste of this expensive material.

- Radii: Avoid sharp internal corners to allow for larger, faster tooling.

Need a Feasibility Review?

PEEK is expensive. Don't risk a failed batch. Our engineering team can review your CAD for stress-relief requirements.

Start Design Review